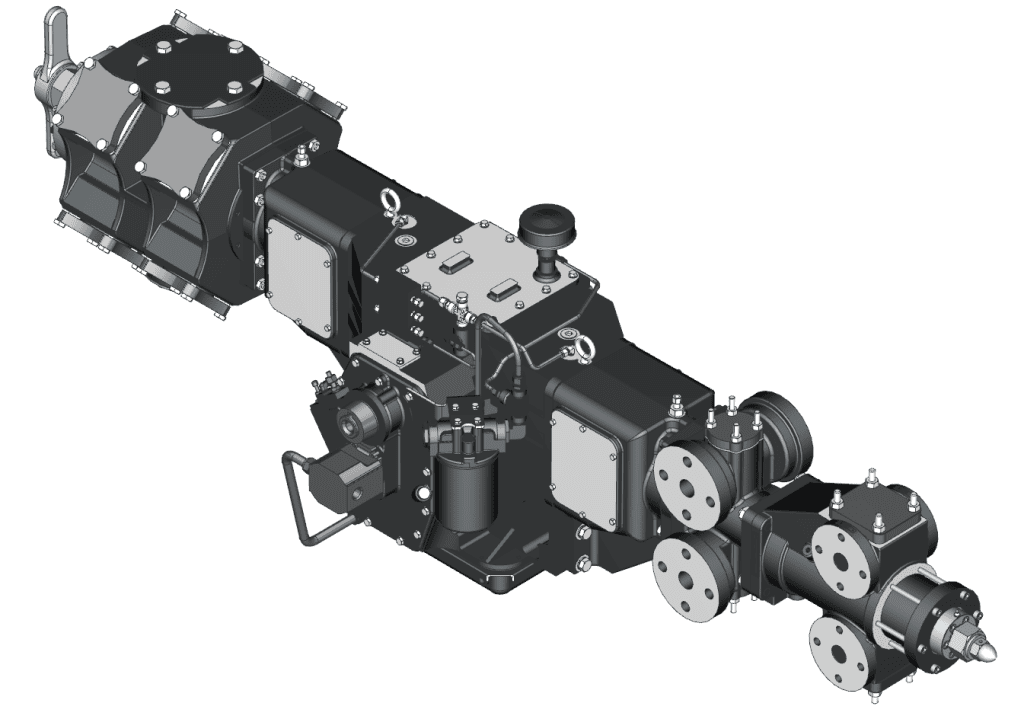

Gemini H302

Compressor Features:

Type - Balanced opposed for a smooth-operating and easy-to-service design. Engineered for reliability and low maintenance.

- Frame - Rugged high-strength frame made from cast iron, with standard type A crosshead guides.

- Crankshaft - Made from forged, heat-treated SAE 4140 steel designed for strength an durability.

- Connecting rods - Ductile iron with precision insert-type bearings on crank end and roller bearings on pin end.

- Crossheads - Single-piece ductile-iron crossheads with babbitted faces and bronze bushings in crosshead.

- Compressor lubrication - Lube system includes gear-driven oil pump, full flow and spin-on 10-micron oil filter for easy servicing.

- Cylinders - A wide range of double acting and tandem cylinders, MAWP up to 6,000 psi.

- Piston/piston rods - Standard piston rods are heat-treated, SAE 4140 steel. Pistons are made from either hard-anodized aluminum alloy or cast iron.

- Valves - Steel valve seats and guards, and non-metallic valve plates are standard. Springs, lift and plates are tailored specifically to your application.

- Cylinder lubrication - Plunger-type force-fed lubricator utilizes a divider block distribution system, a cycle indicator and a DNFT no-flow shutdown switch.

- Standard testing - Standard compressor mechanical no-load spin test and hydrotesting of all cylinders and heads.

- Standard accessories - Specialized tools, where applicable, are included in the toolbox.

Compressor Technical Specifications:

No. of cylinder throws: 2

Max RPM: 1,800

Max power (hp/kW): 200/149

Stroke (in/mm): 3/76

Main bearing diameter (in/mm): 3/76

Piston road diameter (in/mm): 1.125/29

Combined rod loads* (lbs/kN)

Frame weight (lbs/kg): 1,050/476Tension: 10,000/44

Compression: 10,000/44

Total: 20,000/89

*Combined rod load = gas load + inertia load

Compressors can be painted to customer specifications.

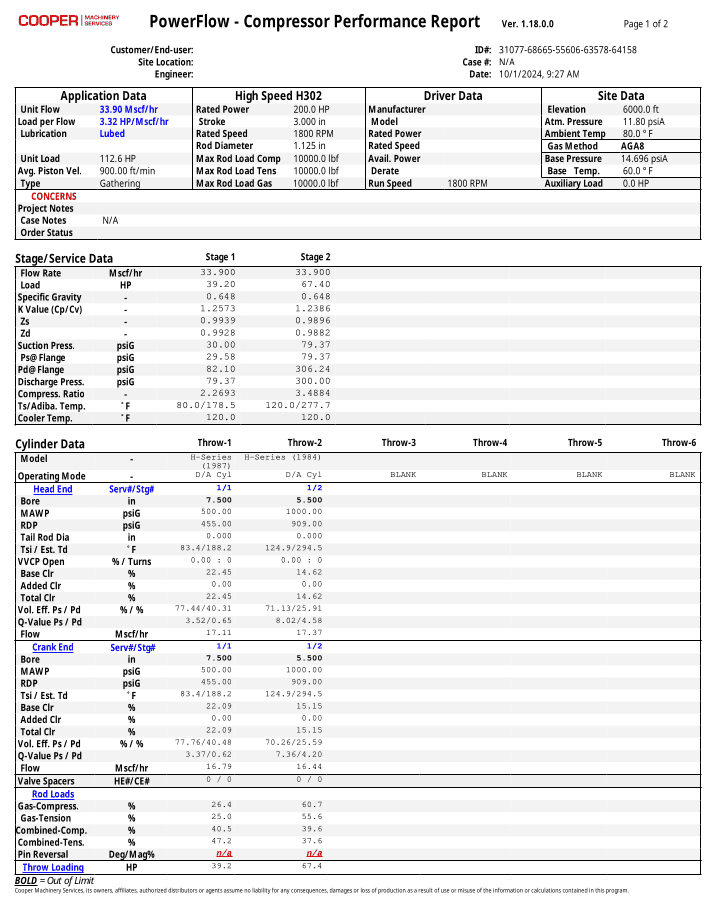

Gemini H302 Performance Report

Providing quality service since 2012.