Low Voltage Solutions

Transcendence provides low voltage solutions that integrate with our compression services for a streamlined operation. Available as standalone options, they can be customized to fit your existing system, ensuring convenience and quality performance.

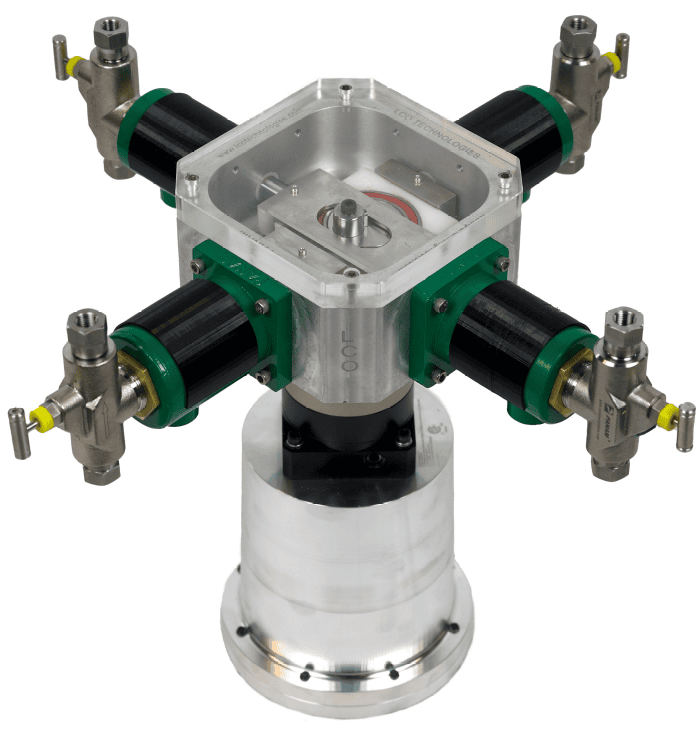

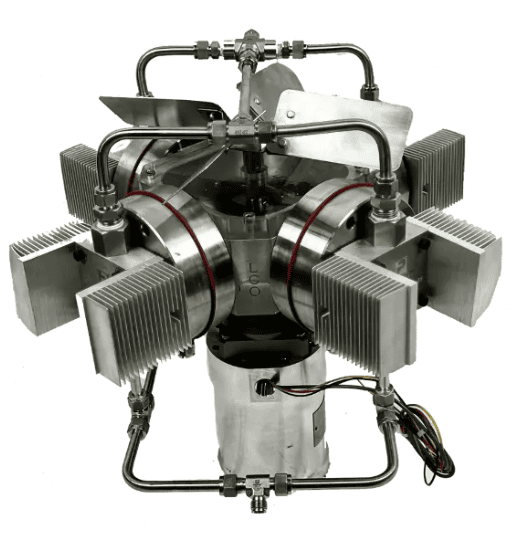

The Crossfire is a quad head pump. One pump = Four pumps

Each yoke can replace an. existing chemical pump.

Features

- Eliminated methane venting from chemical injection

- Precise chemical injection

- Delivers chemical proportionate to flow

- Consistent chemical dispersion rate

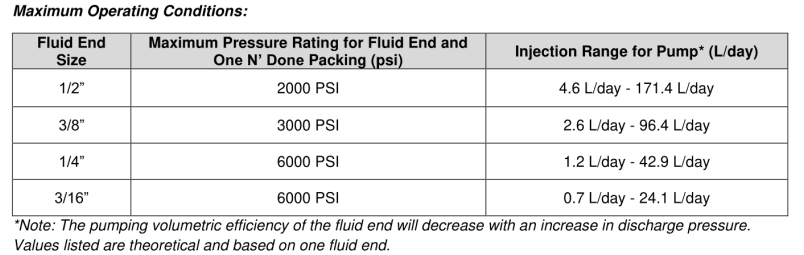

- Each fluid end can be configured for maximum operating conditions:

- High system autonomy

- Ultra-low power chemical injection pump that can run weeks, not days

- Most applications use less power than an 8-watt LED light bulb

- Standard 5100 series fluid ends for field familiarity with proprietary One N' Done packing

- One N' Done deal has superior chemical compatibility and resiliency in a broad range of applications

- Multi-purpose, single piece, spring loaded seal eliminates frequent site trips to adjust packing compression and dramatically reduces replacement of packings

- Industry familiar chevron vee packings also available

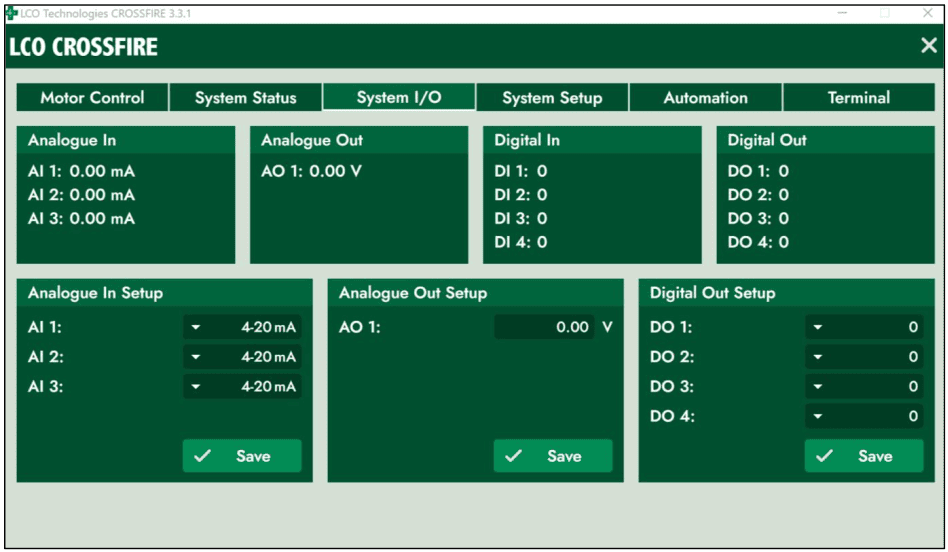

- Comes complete with a smart controller that has MODBUS communications built in as a standard

- Option to upgrade to an advanced controller that has standalone automation capabilities

- Ethernet MODBUS communications

- RS485 or Ethernet

- User friendly operator and technician interface that is password protected

- Mobile and desktop applications

- Bluetooth accessories available for wireless connection and control

- CSA Certified Class 1 Division 1 Motor Assembly

- Efficient, compact, and powerful permanent rare earth magnet motor

- Variable speed drive

- Lifetime lubrication, no maintenance required

Smart Controller Features

- Sophisticated Field Oriented Control (FOC) scheme used to drive the 3-phase rare earth permanent magnet BLDC motor for maximum performance and power efficiency

- Sensorless design with no Hall Effect sensor

- Only 3 (plus ground) standard conductor flex armor cables required to power the motor

- Permanent record of operating data

- Including total stroke counts, volume injected, system status and operating conditions

- Time and date stamped

- Onsite firmware updates available for controller version V38 or later

- Firmware downloadable off the LCO Technologies website

- Built in protection schemes to protect equipment such as: ground-fault, over-voltage, over-current, under voltage, short-circuit, reverse polarity from power supply, unbalanced loading due to broken/loose motor power lines, and fast logic to shut down and isolate motor in the event of faults

- Direction of motor rotation is reversed automatically every month to minimize natural wear and tear

Process Control and Programmable Logic

- Specific programmable logic and control algorithm can be developed to meet customer needs

- Fail-safe motor soft stop feature

- Freeze protection to automatically increase volume injected based on ambient temperature

- Serial communication to a data modem, RTU or flow computer, Bluetooth module, or HMI

- Supports standard MODBUS/RTU protocol for remote control and monitoring

- Ethernet MODBUS/TCP communication available on Advanced controllers V38 or later

- 124 registers per poll for quick, efficient communications

- Built-in process control functions such as toggle switch control and timer control

- Multiple digital and analog IO's to transmitters and final control elements

Features

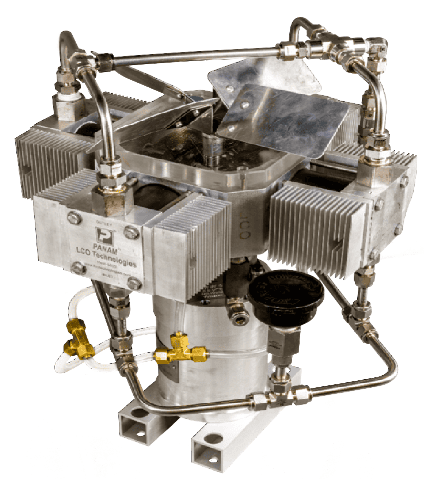

- Produces clean, dry, compressed air to dried low-bleed pneumatic instrumentation

- Eliminates methane venting

- Low power consumption with no inrush

- Rated for continuous duty

- Produces over 1400 SCFD (50 SCFH) at 35 PSI

- Special model for high pressure service (maximum 100 PSI) available upon request

- Automatic speed modulation when used with a pressure transmitter

- Optimize power consumption

- Pre-set configuration at 35 PSI and 50 PSI

- Simple robust design with easy field serviceability

- Minimal Maintenance required

Explosion Proof Motor Assembly

- Zone 1: Class 1, Divison 1 Group CD T6 Explosion Proof Motor Assembly

- Voltage: 24 VDC

- Ambient Temperature: -40 C to +60 C

- Efficient, compact and powerful permanent rare earth magnet motor

Planetary Gearbox

- Designed to withstand tangential force up to 400 ft/lbs

- Single stage design for optimal efficiency with high torque

- Closed casing to keep dust and contaminant free

- Lifetime lubrication, no maintenance required

Smart Controller Features

- Field Oriented Control (FOC) used to drive 3-phase rare earth permanent magnet certified brushless DC motor for maximum torque performance and efficiency

- Sensorless design with no hall effect signal required for control

- Only 3 (plus ground) standard conductor flex armor cables required to power the motor

- 8 LED lights included for easy system monitoring and troubleshooting

Process Control and Programmable Logics

- Specific programmable logic and control algorithms can be developed to meet customer needs

- Built-in process control functions, such ans proportional, ratio and feedback controls

- Multiple digital and analog IO's available for advanced control

- Serial communication to a data modem, a flow computer or a HMI

- Supports standard MODBUS/RTU protocol for remote control and monitoring

- Built in data logging (time and date stamped)

Features and Specifications

- Capture up to 2.519 scfm (3627 scfd) with input pressure of 15" water column and output pressure of the 5-10 psid

- Precise pressure control to maintain tank pressure

- Modulate RPM automatically to collect the gas that varies in the release magnitude

- Tightly control the backpressure while ensuring no vacuum conditions are present

- Maintain blanket gas by maintaing a set pressure that can be customized with our CROSSFIRE app in minutes

- Oil field topworks for lubrication

- Quarterly oil chanes required for regular maintenance (~5 minutes of work)

- User friendly operator and technician interface for configuration and monitoring

- Mobile (Apple and Android) and desktop applications

- Bluetooth accessories available for wireless connection and control

- CSA Certified Class 1 Divison 1 Motor Assembly

- Effiecient variable speed drive permanent rare earth magnet motor

- Lifetime lubrication, no maintenance required

- CSA Certified Class 1 Divion 2 Controller

- Complete with serial (RS232 or RS485) and Ethernet MODBUS communications

- Ethernet 124 registers per poll for quic, effiecient communications

- Standalone automation capabilities with multiple analog and digital inputs/outputs

Hazardous Area Certifications

- The CROSSFIRE has the following hazardous certifications:

- The Explosion Proof Motor Assembly (Model LCOM-1000)

- CSA certified to Class 1 Division 1 Groups CD T6

- Rated input 24 VDC, 9.9 Amps, 750 rpm maximum, Class B, Continous Stall Current 11 A, Rated Output Power 190W

- Ambient Temperature: -40 C to +60 C

- The Smart Controller (Model LCOC-1000-A and a Model LCOC-1000-B)

- CSA certified to Class 1, Divison 2, Groups CD T4

- Rated Input 24 VDC, Vac, 9.9 Amps

- Rated Output 24 VDC, 9.9 Amps

- Ambient Temperature: -40 C to + 60 C

Energy Efficiency

- The LCO patented design is extremely energy efficient

- Assuming that a standard horsepower motor uses 750 Watts of power, our CROSSFIRE 1/4 horsepower motor and VRU uses 2.5A-4A of current at 24 VDC, yielding 84-96 W of power at full load

- It will use significantly less power on a slower RPM, and is almost entirely linear in consumption as the unit is a brushless, contactless in-rush free motor

- Compared to a standard 1/4 horsepower motor at 186.4 W, it is 54.9% more efficient per SCF

- Viable solar technology

CROSSFIRE Telemetry

CROSSFIRE products feature an intuitive digital monitoring system with the following key features:

- Mobile version for cell phones and tablets using Bluetooth comms

- Able to monitor motor status and system status

- Equipped with motor control and switch control

- Keeps a system record that is easily accessible

Transcendence is partnered with LCO Technologies

Providing quality service since 2012.