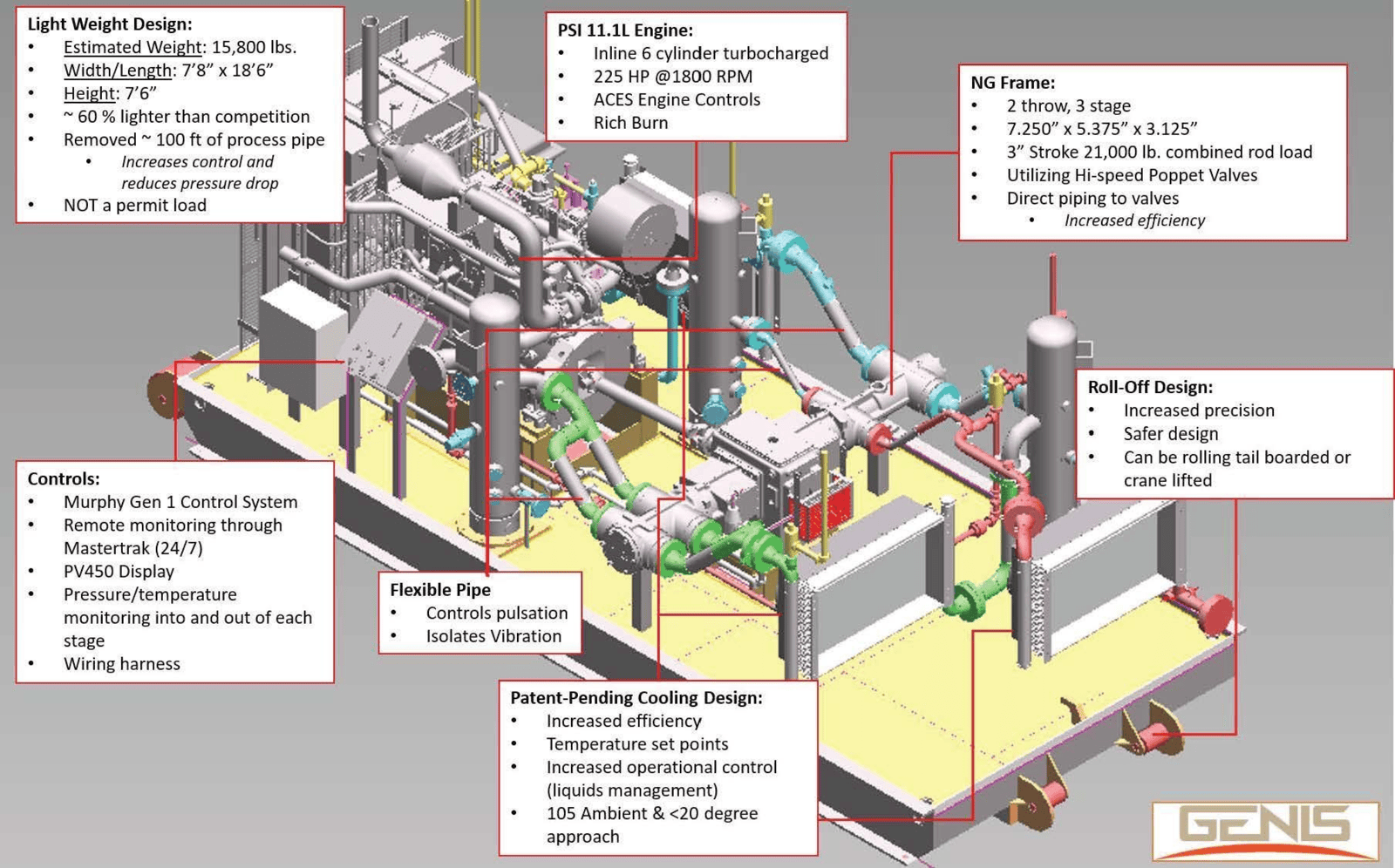

Genis G225 HP

Compressor

• NG MAKO 225 (2 throw, 3 stage)

• 3” Stroke 21,000 lb. combined rod load

• 6.50” DA Cylinder MWP 600 psig

• 4.00” SAHE Cylinder MWP 1250 psig

• 2.00” SAFE Cylinder MWP 3050 psig

Engine

• PSI 11.1L industrial engine rated 228 HP @ 1800 RPM

• Ratings- Elevation ~3000’ and 100 F Ambient

• Inline Six Cylinder Turbocharged 673 Cubic Inches

• EICS Electronic engine control system

• Industrial grade exhaust silencer

• Electronic governor controlled

• Standard 24V starter w/ battery/alternator system

• Rich Burn

• Engine-driven radiator

Coolers - Fresco AC225

• Air-cooled, forced draft, electric fan powered via alternator

• Programmable individual interstage temperature control

• Finned Tube type high efficiency

• Designed for 105F Ambient & <20°F approach

• B31.3 process gas sections

• 1st Stage Intercooler section rated @ 1440 psig @ 350 F

• 2nd Stage Intercooler section rated @ 1440 psig @ 350 F

• After cooler section rated @ 3050 psig @ 350 F

Vessels

• Suction: Vertical 10.75” OD 600 psig MAWP @ 150 oF

• 1st Interstage: Vertical 10.75” OD 650 psig MAWP @ 150ºF

• 2nd Interstage: Vertical 10.75” OD 1250 psig MAWP @ 150ºF

• Designed to ASME Section VIII, Division I Code Stamp

with National Board Registration.

• Hydro tested to 1.3 times MAWP

• Automatic liquid level control system

• High level shutdown

• Manual drain valve

Safety

• Process safety valves (PSV) sized for max flow at design

pressures.

• PSV relief piping to atmosphere above head height

• Package Inlet PSV connection provided. PSV by others

• 1st Interstage PSV set @ 600 psig

• 2nd Interstage PSV set @ 1250 psig

• 3rd Discharge PSV set @ 3050 psig

Process Gas Piping

• Made to ANSI B 31.3

• Manual cold gas recycle valve

• Stainless-steel braided flexible piping for 1st stage process gas

Control Panel• 7’8” X 18’6” Structural steel skid, partially concrete filled• One-piece smooth steel deck plate• All piping mounted on stand-offs for ease of cleaning• Environmental rails around perimeter coming to four drain points• Lockable battery box and disconnect

• Murphy GEN 2 Control System Evolution control panel

• Remote monitoring standard through M-Link

• Shock mounted inner panel

• Shutdown interlocks and sensors:

• Compressor:

o High/low suction pressureo High/low interstage pressures (1st & 2nd)o High/low discharge pressureo High discharge temperature each stageo Compressor low lube oil pressureo Compressor no lube oil flowo Compressor low lube oil levelo High scrubber liquid levelo Multi-Spare set of contacts for digital I/O

• Engine:

o Engine low lube oil pressureo Engine low lube oil levelo Engine low coolant levelo Engine high lube oil temperatureo Engine high jacket water temperatureo Engine over speedo Engine high/low intake manifold pressureo Excessive vibrationo Emergency shutdown contacto Fuel gas pressure regulators included

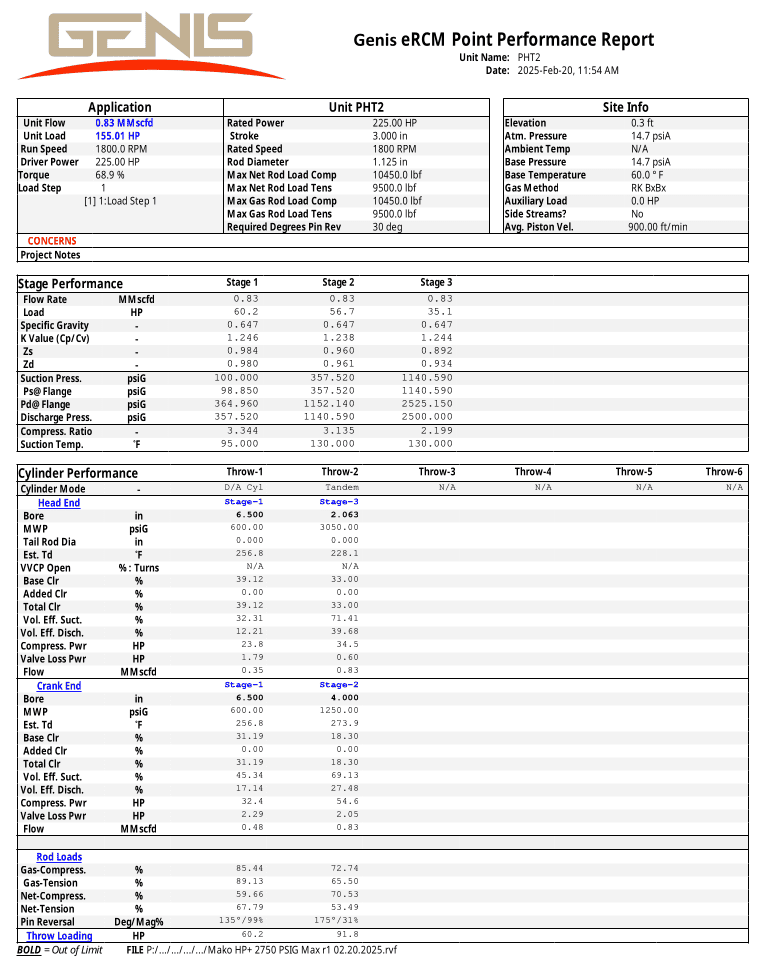

Genis G225 HP Performance Report

Providing quality service since 2012.